Thread Twists: Left Vs Right in Industrial Sewing

In the world of textile manufacturing, the choice of thread can make or break a project. For industrial manufacturers, the debate often centers around left twist and right twist sewing threads. This blog post aims to unravel the intricacies of these two types, ensuring manufacturers make informed decisions. From understanding their properties to knowing which one suits specific applications, we cover it all for textile manufacturers and purchasers alike.

Understanding Industrial Sewing Threads

Industrial sewing threads are pivotal in manufacturing, binding fabrics into finished products. The twist direction—left or right—impacts the thread’s strength and performance. Each type serves unique purposes, offering varying benefits depending on the intended use.

Threads undergo twisting to increase strength and durability. This process involves winding fibers in a specific direction, either to the left or right. The twist direction affects not just the thread’s look but also its performance during stitching, influencing seam appearance and stability. Using a quality thread can enhance performance and durability. A thorough understanding helps manufacturers select the right thread for their specific needs. Additionally, the number of plies and twists within a particular thread can influence its performance.

Why Twist Direction Matters

The twist direction impacts the thread's behavior in machines and its interaction with fabric. Left twist threads are typically used in machines with right-hand configurations, whereas right twist threads suit left-hand machines. This alignment ensures smooth sewing operations and minimizes potential issues like thread breakage or uneven stitches.

Using the correct twist ensures seamless sewing operations. Mismatches can lead to increased tension and friction, causing thread snapping or fabric damage. By aligning the thread twist with machine configurations, manufacturers ensure longevity and efficiency in their production processes.

Comparing Left Twist and Right Twist Threads

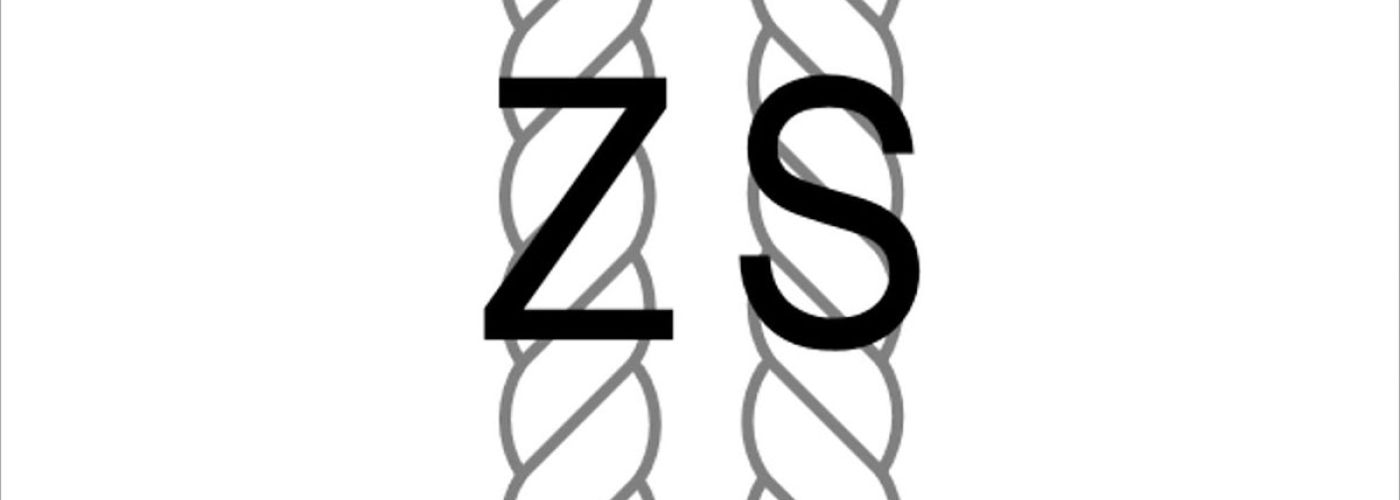

Left twist threads, often referred to as “S-twist,” feature fibers twisted in a counter-clockwise direction. These threads are commonly used in machines with right-hand sewing setups, offering smooth, consistent performance. Right twist, or “Z-twist,” involves clockwise twisting, ideal for left-hand machines. Different levels of twisted thread affect the quality and performance of sewing threads, with higher twist counts resulting in smoother and stronger threads, reducing the tendency to snag or break during use.

Each twist type brings unique advantages. Left twist threads, due to their structure, reduce needle heat and friction, preventing thread damage. Right twist threads enhance stitch tightness, providing secure seams, especially in heavy-duty applications. Understanding these differences empowers manufacturers to optimize their sewing tasks effectively.

Applications of Left Twist Threads

Left twist threads excel in applications requiring minimal friction and heat resistance. They are ideal for lightweight fabrics and high-speed sewing operations where thread integrity is crucial. These threads prevent puckering, ensuring a clean, smooth finish, especially in delicate textiles. Left twist threads are also beneficial in cross stitch to maintain thread integrity and neatness.

Manufacturers often prefer left twist threads for apparel such as shirts and dresses, where appearance is paramount. Their ability to maintain consistent tension reduces the risk of fabric distortion, enhancing the overall garment quality. This makes them indispensable in industries focusing on fashion and lightweight textiles.

Applications of Right Twist Threads

Right twist threads, with their clockwise fiber arrangement, are perfect for heavy-duty applications. These threads provide enhanced seam security, making them suitable for denser fabrics like denim and upholstery. In automotive and furniture manufacturing, their durability ensures long-lasting, robust seams.

The extra strength offered by right twist threads is ideal for products exposed to frequent stress and strain. They withstand wear and tear, maintaining seam integrity over time. This reliability makes them a popular choice among manufacturers producing durable goods and industrial applications. Similarly, managing natural hair styles, such as curly hair styles and 4c hair protective styles, requires durability and strength to maintain the integrity of the hair.

Factors Influencing Thread Choice

Several factors influence the decision between left and right twist threads. Machine configuration is paramount, but fabric type, thread tension, and the final product’s intended use are equally important. Aligning these aspects ensures optimal performance and a high-quality finished product.

Thread material also plays a role. Polyester threads, for instance, offer different characteristics compared to cotton or nylon. Understanding how these materials interact with twist direction helps manufacturers tailor their choices to specific requirements, maximizing efficiency and product quality.

The Impact of Thread on Seam Quality

Thread twist affects seam appearance and durability. The right choice enhances seam strength, reduces puckering, and ensures consistent stitch formation. Manufacturers benefit from smoother, more reliable seams, improving product quality and reducing production costs.

Seam quality directly influences the product's lifespan and customer satisfaction. High-quality seams withstand wear, maintaining their integrity through repeated use. By choosing the appropriate thread twist, manufacturers enhance the end-user experience, leading to positive feedback and repeat business.

Troubleshooting Common Issues

Incorrect thread twist can lead to several issues, including thread breakage, skipped stitches, and uneven seams. Identifying and rectifying these problems is essential for maintaining smooth production lines. Regular machine maintenance and ensuring the correct thread twist alignment mitigate these challenges. Additionally, spinning the needle in your fingers can help keep threads untwisted during stitching.

Manufacturers should also consider needle size and thread tension adjustments. These factors interact with thread twist, impacting performance. By fine-tuning these elements, manufacturers can overcome common sewing issues, ensuring consistent, high-quality results in their products.

Innovations in Thread Technology

Advancements in thread technology continually enhance manufacturing capabilities. New materials and twist methods offer greater efficiency and versatility, catering to diverse industry needs. Staying updated with these innovations helps manufacturers maintain a competitive edge in the textile sector.

Innovative threads incorporate features like UV resistance and antibacterial properties, expanding their applications. These advancements allow manufacturers to explore new markets and product lines, leveraging cutting-edge technology to meet emerging consumer demands and industry standards.

Choosing the Right Supplier

Selecting a reliable thread supplier is crucial for consistent quality. Suppliers with a broad range of left and right twist threads provide flexibility in meeting specific manufacturing needs. Evaluating supplier reliability, pricing, and delivery capabilities ensures a smooth, cost-effective production process.

Building strong supplier relationships fosters mutual growth and innovation. By collaborating with suppliers knowledgeable about the latest thread developments, manufacturers gain insights into new possibilities, enhancing their product offerings and staying ahead in the competitive market.

Conclusion Enhancing Manufacturing Efficiency

Understanding the nuances of left and right twist threads empowers manufacturers to optimize their sewing operations. The right choice enhances seam quality, reduces production costs, and improves product durability. As the textile industry evolves, staying informed about thread technology remains crucial for maintaining competitive advantage and meeting consumer expectations.

By leveraging the insights shared in this post, industrial manufacturers and textile companies can refine their thread selection processes, ensuring efficiency and excellence in their products. For those seeking further information or wishing to explore specific thread options, connecting with industry experts and suppliers remains a valuable next step.

Whatsapp:

Whatsapp: