Quality is Our Benchmark

Raw Material Testing

- Yarn Count

- Length and weight

- Single yarn tension

- Twist per unit length

- Moisture content

- Evenness and hairness

Advanced Machines

- Automatic dispensing system

- Automatic color control system

- Fongs dye machine

- Thies pressire dryer

- SSM automatic winder machine

- Automatic packing machine

Product Quality Control

- Length and weight

- Unwinding performance

- Color fastness and difference

- Thread tension

- Sewing Performance

- Packing

Quality as Corporate Culture

MH Thread Factory takes meticulous measures to ensure the quality of our threads from multiple perspectives.

- Material: MH uses high-quality materials, ensuring each thread exhibits immense strength and a consistent diameter for reliable stitching.

- Grade 4 Color Fastness: MH threads are designed for colorfastness, maintaining their vibrant hues even after prolonged exposure to sunlight or numerous wash cycles.

- Twist Level: MH paies close attention to the twist level of our threads, striking the perfect balance for optimal strength, durability, and aesthetic appeal. The smoothness of our threads is unmatched, eliminating knots and snags for an effortless sewing experience.

- Elongation: Threads also feature controlled elongation, providing just enough stretch to prevent puckering and looping without compromising the integrity of the stitch.

- High-quality Silicone Oil: MH applies careful lubrication to reduce friction, extending the lifespan of your needles and fabric.

OEKO-TEX®-Certified Sewing Threads

The STANDARD 100 by OEKO-TEX® certification is widely recognized as one of the most significant endorsements for textiles. MH sewing thread, constructed from 100% polyester and treated with a select range of 20 disperse dyestuffs, inclusive of fluorescent dyestuff, has earned this esteemed certification. This compliance indicates that our threads meet the stringent requirements necessary for use in baby articles.

OEKO-TEX®-Certified Embroidery Threads

The STANDARD 100 by OEKO-TEX® certification is highly regarded as a crucial endorsement for textile products. MH embroidery thread, manufactured from 100% viscose and subjected to a bleaching and dyeing process using a restricted palette of 10 reactive dyestuffs, has achieved this respected certification. This signifies that our threads adhere to the stringent safety standards required for products intended for infants.

Cutting-edge Thread Manufacturing Technology for Outstanding Quality

Drying and Dyeing Treatments

Fongs Dye Machine: Lower bath ratio, low energy consumption and good dyeing performance.

Thies Pressure Dryer: Economical energy consumption, short time drying and higher efficiency, reducing labour costs by optimisted handling.

Fongs Dye Machine

Thies Pressure Dryer

SSM Automatic Winder

The SSM Automatic Winder is an exemplary piece of machinery, owing to its advanced Lubetex oil injection apparatus. This device is specifically designed to lubricate the yarn efficiently. Furthermore, the heating function that operates on a single-spindle basis ensures the wax is melted more comprehensively and evenly. Consequently, the yarns are entirely enveloped by the lubricating oil, leading to a more uniform oil rate. This meticulous process contributes to the superior quality and performance of the yarn produced.

Winding Machine

The Winding Machine is designed to ensure an optimal cone shape and consistent thread tension. These features significantly enhance sewing efficiency at high speeds while effectively reducing the risk of thread breakage. This contributes to a smoother, more reliable sewing process, thereby optimizing productivity.

High Speed Winding Machine

Ordinary pagoda winding machine

Proofing and Testing Equipment for Guaranteed Quality

Proofing Equipment

Understanding that rapid and precise color recognition is crucial to our clients' success, we have implemented a highly efficient and effective process to ensure swift delivery. This procedure begins with the deployment of our specialized color teams, complemented by the use of state-of-the-art color measurement equipment. Our commitment to this approach underscores our dedication to meeting our customers' needs with accuracy and speed.

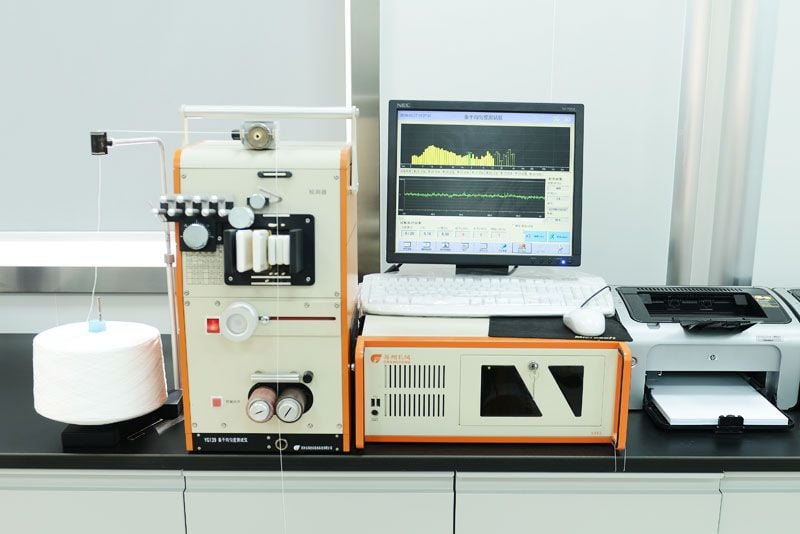

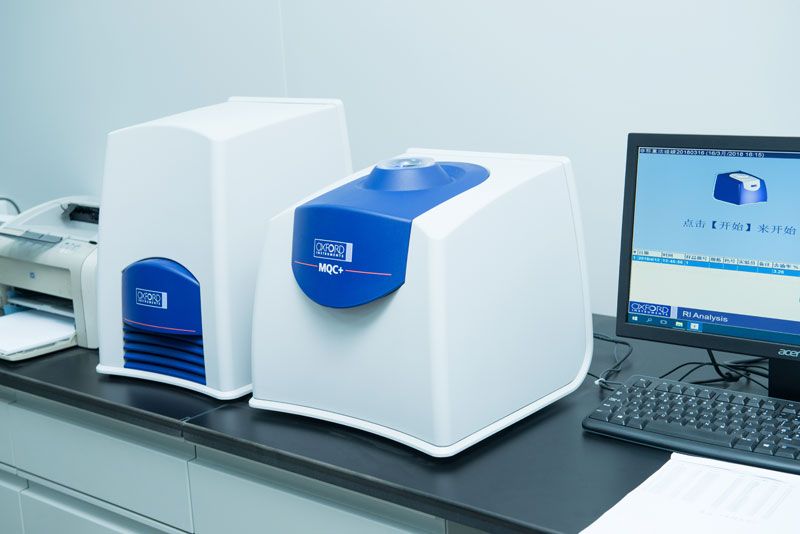

Testing Equipment

MH testing center is equipped with a comprehensive suite of testing equipment. Prior to initiating the production process, raw materials are subjected to rigorous testing. Upon completion, the finished sewing thread undergoes thorough evaluation for parameters such as uniformity, hairiness, tensile strength, color retention, and sewing performance.

We ensure that only those threads which meet our stringent quality standards are dispatched to our valued customers. This meticulous approach underscores our unwavering commitment to delivering superior quality products.

Whatsapp:

Whatsapp: