Sewing Machine Needle Types and Sizes Selection Guide

- Key Takeaways

- Types of Sewing Machines Needles

- The Anatomy of Sewing Machine Needles

- What is the Difference Between Machine Embroidery Needles and Sewing Needles?

- Needle Size System

- Machine Needles for Different Fabrics

- Specialty Sewing Needles

Needle types can significantly impact your sewing. This article will guide you through different needles and their specific applications. Discover how to select the perfect needle for your projects to enhance your sewing experience.

Key Takeaways

-

Choose the right needle type for your fabric: universal, embroidery, leather, and quilting needles each serve different purposes.

-

Understand needle anatomy—parts like the eye and point affect sewing performance, ensuring better stitch quality.

-

Regularly change and properly store your needles to maintain quality and prevent issues like poor stitching or fabric damage.

Types of Sewing Machines Needles

When it comes to sewing machine needles, there’s a needle for every fabric and stitching requirement. Understanding the various types can save you from a lot of frustration and ensure your sewing machine performs at its best.

-

Universal Needles:The universal class of needles are used on domestic machines. "Universal" refers to the shape of the needle shank and length of the needle rather than the actual sewing application or point. The most notable feature of universal needles is the flat face on the needle shank which helps to ensure the needle is inserted correctly. A universal class needle is designed to be used on virtually any domestic sewing machine. They do not fit industrial or commercial machines.

-

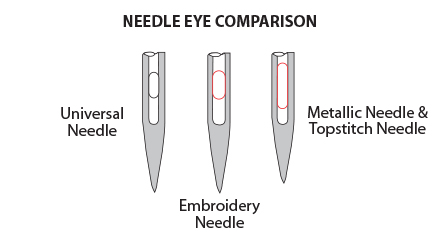

Embroidery needles are designed specifically for machine embroidery. They feature an extra-large eye and a specially shaped scarf to prevent delicate embroidery threads from shredding.

-

Metallic Needle: Similar to an embroidery needle with a large eye and extra long scarf, but also includes a Teflon coating to the eye so that metallic threads will not shred when used.

-

Ballpoint Needles is similar to a universal needle but features rounded edges and a different tapering design. It is specifically designed for tightly woven fabrics, using its rounded tip to gently push the weave aside rather than piercing or damaging it.

-

Jeans/Denim Needle: Intended for tightly woven cottons such as canvas. Has a strong, sharp point and very slender eye.

-

Wing Needle: Needle has distinct "wings" on either side of the eye which hold the fabric open. Often used on hems and borders, and for decorative finishing. A larger size needle will leave a larger hole in the final piece of sewn fabric.

-

Leather Needles, with their distinct triangular point, are ideal for non-woven materials like vinyl and genuine leather. A leather needle, which features a Teflon coating on the eye to prevent thread shredding, is perfect for working with metallic threads.

Click here to learn more about the Leather Needle for Singer Sewing Machine -

Quilting Needles, designed for quilting and appliqué, have an extra strong shaft and a tapered point to penetrate multiple fabric layers without breaking.

-

Serger/Industrial Needle: These needles can only be used in serger and overlocking machines.

Click here to learn more about Overlock Needles -

Microtex/Sharps Needle: More slender and sharper than the universal needle. Suitable for fine woven fabrics, but also compatible for quilting and appliqué.

-

Stretch Needle: These needles are intended for use on fabrics with significant amounts of Spandex or similar fabric content. Rounded tip and specialized scarf and eye to prevent skipping.

-

Topstitching Needle: These have exceptionally sharp points and a large eye to accommodate thick decorative topstitching threads. Very similar to the leather needle.

-

Twine/Triple Needle: Needles set in pairs or in groups of three on a single shaft designed to sew multiple, usually decorative, threads at once. These require specialized machinery to accommodate the extra needles, as well as multiple thread feeds. Another needle type specification usually accompanies the twin or triple designation such as "stretch" or "denim", etc.

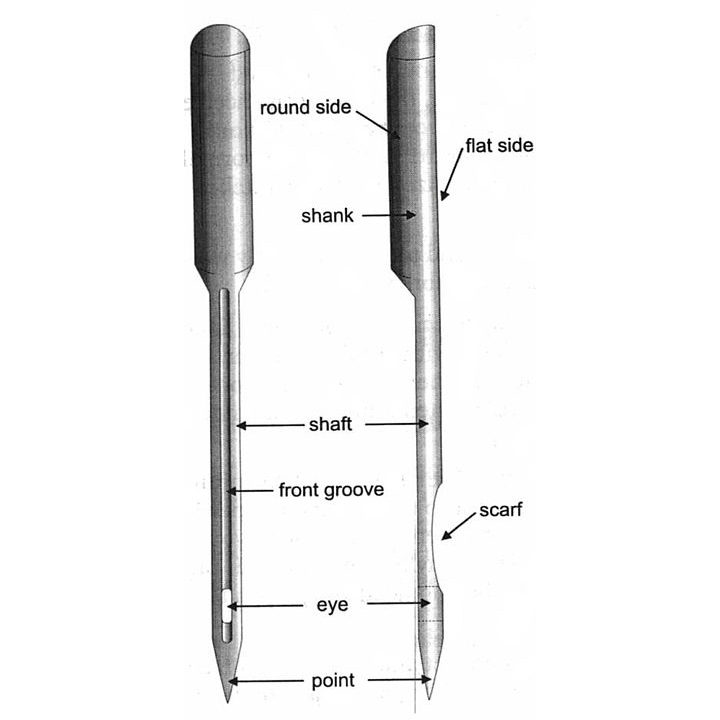

The Anatomy of Sewing Machine Needles

-

The Shank (the flat and rounded part): This is the part you use to mount the needle on to the machine. It is the flat and round part you see on the needle.

-

The Shaft: This is the length that spans from the end of the shank to the tip of the needle. It includes the Groove, the eye and the tip of the needle.

-

The Groove: This is the rest of the needle that spans from the shaft down to the pointy tip, including the eye and the tip.

-

The Eye: This is the part where the sewing thread passes through. The eye must work with the thread. For example, a topstitch needle has a bigger eye to accommodate a thicker thread.

-

The Point: Depending on the needle’s use, the point can be sharp or rounded. Standard needles are sharp while ballpoint needles have a rounded point like a ball.

What is the Difference Between Machine Embroidery Needles and Sewing Needles?

Although embroidery and sewing machine needles can be used for machine embroidery, they differ in the shape of the eye and scarf. Embroidery needles have a longer eye and a specially shaped scarf to accommodate delicate threads, preventing breakage or fraying.

Using the wrong needle can lead to thread breakage and poor stitch quality. Therefore, selecting the correct sewing machine needle is key to achieving beautiful, durable embroidery.

The Anatomy of Embroidery Machine Needles

Embroidery machine needles share parts like the shank, shaft, eye, groove, and point with regular sewing needles, but their design caters specifically to embroidery work.

The shank fits securely into the needle holder, and the shaft is engineered for repeated punctures through fabric and stabilizer. A larger eye accommodates thicker or multiple threads, while the groove ensures the thread sits close to the needle, reducing friction and preventing breakage.

Click here to know how to choose the right embroidery machine needle

More on Machine Embroidery Needles

Point: Machine embroidery needles usually have a slightly rounded universal point, suitable for most fabrics and stabilizers. For very fine stabilizers, a sharp point needle is recommended to penetrate without ripping the material.

Size: Embroidery needles range from 70 to 110 mm in size. The choice depends on the fabric, stabilizer, thread, and stitch density of your design. For heavy-duty projects, titanium needles are ideal due to their durability and shape retention.

Needle Size System

The needle size system can be confusing initially, but understanding it is crucial for choosing the right needle. The Number Metric (NM) system, established in the 1940s, standardizes sizes by measuring the needle shaft diameter in millimeters and multiplying by 100.

So, a standard “80” needle is actually 0.80mm in diameter. The second number in the needle size, like the “12” in an 80/12 needle, comes from the corresponding Singer or US system. This dual-number system helps sewers understand the needle’s thickness and strength.

-

60/8 – used for fine fabric like lingerie, silk and fine lace.

-

65/9-used for fine fabrics like silk, chiffon, organza, voile, lace)

-

70/10 – used for fine fabrics like Net, Chiffon Lingerie, silk and cotton

-

75/11 – Light weight fabrics like Voile, Chiffon, Organza, Denim, Satin, Sweater, Silk, Dress Shirt, Lycra, Spandex etc.

-

80/12 – Light weight fabrics Tricot, Silks, Canvas

Click here to know more about Machine Sewing Needle for Canvas -

90/14 – Medium weight fabrics like Syn Velvets, Poplin, Linen, Light Wool, Jersey, Muslin etc.

-

100/16 – Heavy weight fabrics like cord, Denim, Heavy Suiting, Corduroy etc.

-

110/18 – Heavy weight fabrics like heavy Denim, Leather, Upholstery Fabric, Faux Fur etc.

-

120/19 – Very heavy weight fabrics like super heavy fabrics: Cord, Denim, Heavy Suiting

-

125/20-Extra heavy fabrics

-

130/21-Extra heavy fabrics

What to consider when choosing a sewing machine needle

When choosing a sewing machine needle, consider the thickness, as thicker needles suit heavier fabrics, while thinner needles are better for fine fabrics like silk and chiffon.

The needle’s purpose also matters. For instance, leather-specialized needles are sharper to penetrate tough materials easily. The type of thread can also influence needle choice. Fine, delicate threads work best with smaller needle sizes.

Click here to know how to replace a needle for brother sewing machine.

Machine Needles for Different Fabrics

Choosing the right needle for your fabric ensures the best results. Different fabrics require specific needle types for smooth stitching and to prevent damage.

Universal Needles: Universal needles are versatile and compatible with various fabrics, including woven and synthetic materials, making them ideal for general sewing projects.

Ball Point Needles: Ball point needles, designed for knit fabrics, have a rounded tip that pushes fibers apart rather than cutting through them, preventing snags and runs.

Stretch Needles: Stretch needles are perfect for sewing elastic fabrics. Their special scarf prevents skipped stitches, ensuring a smooth, consistent seam.

Quilting Needles: Quilting needles, or Betweens Needles, handle multiple fabric layers without bending or breaking. Their shorter length allows for quick and even stitching.

Jeans/Denim Needles: Jeans needles, designed for heavy fabrics like denim, have a strong shank and a very sharp point, ideal for penetrating thick materials.

Click here to learn more about

Leather Needles: Leather needles, with their chisel point, effectively cut through tough materials like genuine leather and suede. Use these needles exclusively for leather to avoid damaging other fabrics.

Specialty Sewing Needles

Specialty sewing needles cater to specific applications and unique materials, enhancing the sewing experience. They include sewing needle types such as metafil needles, twin and triple needles, and wing needles.

Metafil Needles

Metafil needles, designed for sewing with metallic threads, have an extra-large eye to prevent thread shredding and facilitate easier threading with a metallic needle.

Twin and Triple Needles

Twin and triple needles enable unique stitching techniques, such as creating parallel lines and decorative seams, making them ideal for pin tucks and decorative stitches.

Wing Needles

Wing needles create holes for drawn thread work and are most effective on natural fiber fabrics like cotton.

Choosing the Right Needle Size

Selecting the correct needle size is crucial for achieving optimal sewing results. Needle size numbers indicate both European and American sizes, usually ranging from 60 to 110 in Europe and 8 to 18 in America. A larger number denotes a finer and shorter needle.

Using the correct needle size for your fabric prevents issues like poor stitch quality and needle breakage. For instance, a 16/100 needle is recommended for dense fabrics like denim, while finer needles suit lightweight fabrics.

Tips for Maintaining Needle Quality

Maintaining needle quality is vital for consistent sewing performance. Regular replacement and proper storage can prevent fabric damage and ensure smooth stitching.

How Often Should You Change Your Needle?

Change your sewing machine needle after every project. Signs indicating a need for change include poor stitch quality or unusual machine sounds. Regular needle changes maintain stitch quality and prevent fabric damage.

Proper Needle Storage

Store hand sewing needles in protective cases to maintain quality and avoid damage.

Magnetic needle holders are also effective for keeping needles organized and accessible.

Summary

Choosing the right sewing machine needle is integral to the success of any sewing project. From understanding the different types and their applications to selecting the correct size and maintaining needle quality, this guide has covered all the essential aspects.

With the knowledge gained, you can confidently select the right needle for your sewing projects, ensuring beautiful, high-quality results every time. Happy sewing!

Frequently Asked Questions

- How often should I change my sewing machine needle?

You should change your sewing machine needle after every project or every 6-8 hours of use to keep your stitches looking great and protect your fabric. It's a small step that makes a big difference! - Can I use embroidery needles for regular sewing?

Yes, you can use embroidery needles for regular sewing, but it’s better to use regular sewing needles for everyday tasks since they are specifically designed for that purpose. - What needle size should I use for denim?

For sewing denim, a needle size of 16/100 is your best bet to achieve smooth stitching and avoid any breakage. This size is perfect for tackling those dense fabrics! - How do I store my sewing needles properly?

To properly store your sewing needles, use protective cases or magnetic needle holders to keep them safe and in good condition. This simple step can really extend their lifespan! - What are the signs that I need to change my sewing machine needle?

If you're noticing poor stitch quality, strange sounds from your machine, or frequent thread breakage, it's definitely time to swap out your sewing machine needle. Keeping your needle fresh can make a big difference in your sewing experience!

Other Related Topics

- What Needle to Use for Stretch Fabric

- Ballpoint Hand Sewing Needles

- What Size Sewing Machine Needle for Cotton Fabrics?

- Choosing the Right Crewel Embroidery Needle

- Needle Thread Size Chart

- Sewing Pin Sizes and Types

- V69 Thread Needle Size: Bonded Thread Guide

- Choose the Right Sewing Needle: Types and Sizes

Whatsapp:

Whatsapp: