High Temperature Sewing Thread

In the textile and garment industry, choosing the right materials is crucial—especially when it comes to sewing threads that can withstand high temperatures. This guide will introduce you to high temperature sewing threads, explore their applications, and explain why they are pivotal for factories focusing on durability and safety. Whether you're managing a garment or textile factory, understanding the benefits of these specially designed threads can revolutionize your production processes.

Understanding High Temperature Sewing Thread

High temperature sewing threads are engineered to endure extreme conditions without sacrificing strength or flexibility. These threads are manufactured using heat-resistant fibers, making them suitable for applications where traditional threads would fail due to insufficient break strength. Additionally, the breaking strength of these threads is a critical factor, indicating their capacity to withstand tension in both imperial and metric measurements. Factories that specialize in products exposed to heat, such as protective garments, automotive interiors, or industrial textiles, rely heavily on these threads.

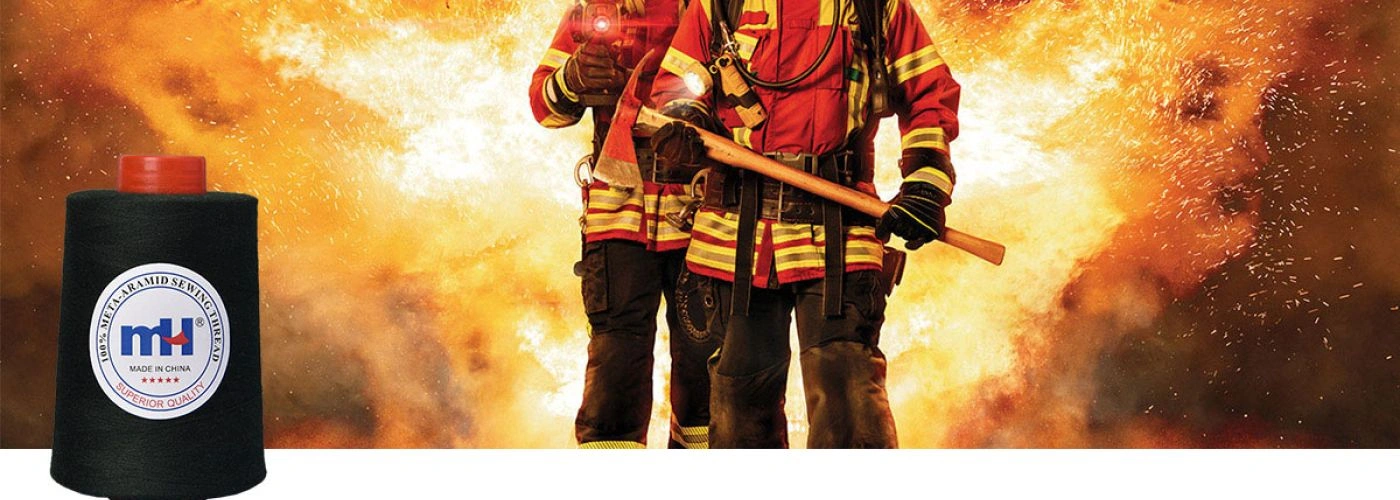

The importance of using the right thread cannot be overstated. A garment stitched with unsuitable thread may unravel under stress, leading to product failure. High temperature threads maintain their integrity even under intense heat, ensuring that seams remain secure. This reliability is crucial in industries where safety and performance are paramount, like firefighting or military apparel.

When selecting high temperature sewing thread, consider factors such as fiber type, heat tolerance, and tensile strength. Each thread type offers unique properties tailored to specific needs. Understanding these differences will help you choose the best option for your production line, ensuring both quality and safety in your finished products.

Benefits of High Temperature Sewing Thread

The advantages of high temperature sewing threads extend beyond mere heat resistance. Understanding the continuous operating temperature of these threads is crucial for optimal sewing performance and durability. These threads provide enhanced durability, ensuring that seams remain intact even under challenging conditions. This durability translates into longer-lasting products, reducing the need for frequent repairs or replacements.

Another significant benefit is the thread’s ability to maintain color and integrity despite exposure to harsh conditions. Traditional threads may fade or weaken over time, but high temperature threads are designed to withstand environmental stressors without compromising aesthetic or structural qualities.

Finally, using high temperature threads can improve overall product safety. In industries where materials are exposed to flames or high heat, these threads play a critical role in preventing accidents. By choosing the right thread, factories can enhance the safety profile of their products, protecting end-users and mitigating liability risks.

Exploring Aramid Sewing Thread

Aramid sewing thread is a popular choice within the high temperature category due to its exceptional heat resistance and strength. Made from aramid fibers, this thread can resist temperatures up to 500 degrees Fahrenheit without degradation, and its diameter plays a crucial role in determining its temperature limitations, yield strength, and break strength, making it ideal for extreme conditions.

The use of aramid thread is widespread in industries requiring flame-retardant materials, such as aerospace, automotive, and protective clothing. Its superior strength-to-weight ratio also makes it a preferred choice for high-performance applications where weight is a concern.

In addition to heat resistance, aramid threads offer resistance to abrasion and chemicals, enhancing their versatility. Factories opting for aramid threads can produce durable, reliable products capable of performing in demanding environments, thereby meeting stringent industry standards.

Applications of High Temp Thread in Garment Factories

Garment factories utilize high temp threads in various applications where heat resistance is essential. One primary application is in the production of protective clothing, such as firefighters’ suits or military uniforms. These garments require seams that can withstand both heat and pressure, ensuring the wearer’s safety in hazardous environments.

Another application is in the construction of automotive interiors. High temp threads are used in seat covers, airbags, and seatbelts, where durability under heat stress is critical. These components must not only resist daily wear and tear but also perform in emergency situations where lives depend on their reliability.

In the realm of industrial textiles, high temp threads are used to manufacture items like conveyor belts, filtration fabrics, and thermal insulation covers. These products must endure continuous exposure to high temperatures while maintaining their structural integrity, making high temp threads an indispensable component in their construction. Reusable insulation blankets, specifically designed for high resistance to heat, also require specialized sewing threads to ensure durability and functionality in extreme environments.

How to Choose the Right High Temperature Thread

Selecting the appropriate high temperature thread for your needs involves understanding your specific requirements and the properties of available threads. Consider factors such as the maximum temperature the thread will encounter, the type of material it will be sewn into, and any additional environmental factors like exposure to chemicals or UV light.

It’s also important to evaluate the thread’s tensile strength and elasticity. A thread that is too stiff may cause puckering, while one that is too stretchy may not hold seams securely. Matching the thread’s physical properties to the intended application ensures optimal performance and longevity.

When in doubt, consult with thread manufacturers or suppliers who can provide detailed specifications and recommendations based on your specific needs. Leveraging their expertise can help you make informed decisions, ultimately leading to better product quality and customer satisfaction. Additionally, you can consult your sales rep for more high-temperature sewing thread options that may not be listed in the catalog, ensuring you receive personalized assistance.

Common Challenges with High Temperature Threads

While high temperature threads offer numerous benefits, they also present unique challenges. One common issue is compatibility with sewing machines. These threads can be thicker and less flexible than traditional threads, potentially requiring adjustments to machine settings or the use of specialized equipment.

Another challenge is ensuring the thread’s colorfastness and appearance. High temperature threads may have limited color options, and achieving consistent dyeing results can be more complex. For instance, the range of colors, including yellow, diminishes as the operating temperature increases. This limitation can affect the aesthetic appeal of products, particularly in fashion-forward industries.

Lastly, high temperature threads can be more expensive than standard threads, impacting production costs. However, the increased durability and safety they provide often outweigh the initial investment, leading to cost savings in the long run through reduced maintenance and liability expenses.

Innovations in High Temp Thread Technology

Advancements in textile technology continue to improve the performance of high temp threads. Quartz sewing thread, known for its capability to withstand extreme temperatures up to 2000°F (1093°C), is a notable innovation in this field. New developments focus on enhancing heat resistance, durability, and environmental impact, providing manufacturers with more options to suit diverse applications.

One area of innovation is the development of hybrid threads that combine different fibers to achieve superior properties. These threads offer enhanced flexibility, strength, and resistance to multiple environmental factors, broadening their applicability across industries.

Additionally, sustainable manufacturing practices are gaining traction, with more companies seeking eco-friendly alternatives. This shift includes the use of recycled materials and processes that reduce energy and water consumption, aligning with global efforts to minimize environmental impact.

Importance of Quality Control in High Temp Thread Production

Ensuring the quality of high temp threads is vital for maintaining product integrity and safety. Manufacturers must implement rigorous quality control measures to verify that threads meet specified performance standards before deployment in production.

Key quality control processes include tensile strength testing, heat resistance assessments, and chemical exposure evaluations. These tests help identify any weaknesses or inconsistencies in thread batches, allowing manufacturers to address issues proactively.

Regular audits and inspections of production facilities further support quality assurance efforts. By maintaining high standards throughout the manufacturing process, companies can deliver reliable, high-performance threads that meet customer expectations and regulatory requirements.

The Future of High Temperature Sewing Threads

The future of high temperature sewing threads lies in continued innovation and adaptation to meet evolving industry demands. As technology advances, threads will become more efficient, versatile, and sustainable, supporting new applications and improving existing ones.

Increased collaboration between thread manufacturers, fabric producers, and end-users will drive the development of specialized solutions tailored to specific needs. This collaborative approach ensures that new products are both practical and effective, meeting the highest standards of quality and safety.

Ultimately, high temperature threads will play an increasingly important role in advancing textile technology, offering manufacturers new opportunities to create durable, reliable, and innovative products that stand the test of time.

Conclusion

High temperature sewing threads are essential for producing durable, safe, and reliable products across a wide range of industries. By understanding the properties, applications, and benefits of these threads, garment and textile factories can make informed decisions that enhance product quality and performance.

Investing in high temp threads not only improves the safety and durability of products but also offers significant cost savings and competitive advantages. By staying informed about the latest advancements and best practices, factories can continue to innovate and deliver exceptional results for their customers.

Whatsapp:

Whatsapp: