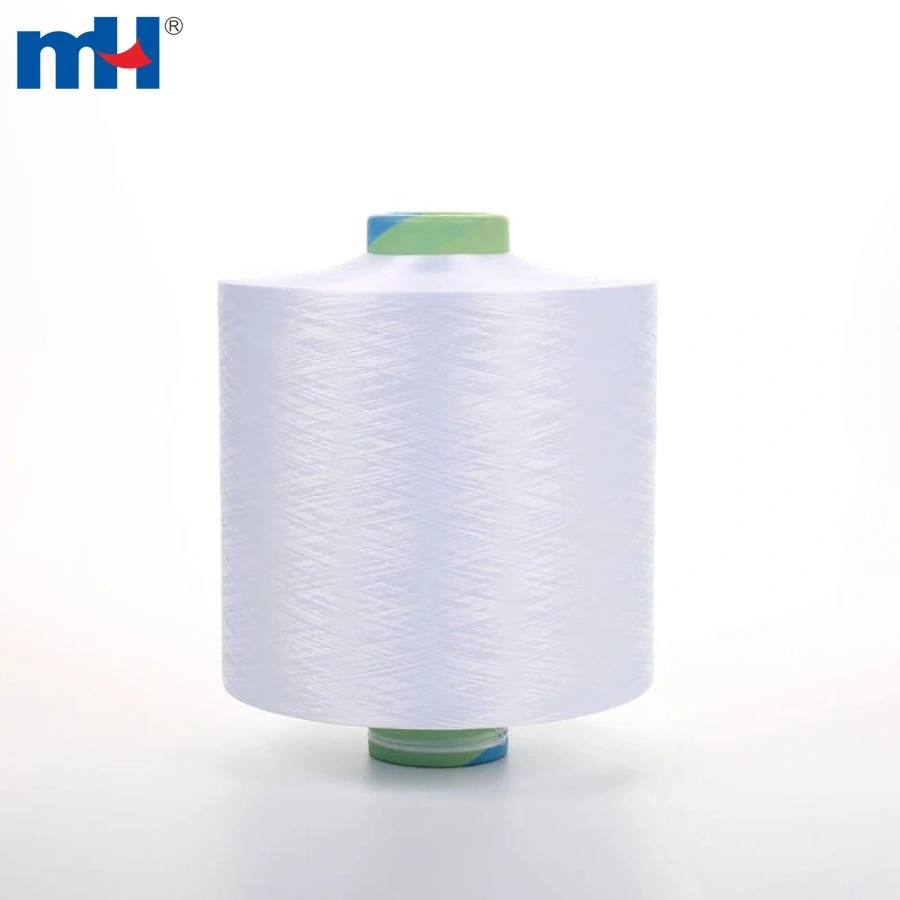

Polyester Yarn DTY 300D/96F NIM HIM (SD RW AA GRADE)

- Material: 100% polyester

- Spec: 300D/96F DTY yarn

- Yarn type: Draw textured yarn

- Packing: Custom

- Quality: High AA grade

-

Most samples are free, while a few may require a purchase; shipping costs are the responsibility of the recipient.

- Lead Time: 25-35 days

- Shipping: Sea freight, Railway freight

- Payment: T/T, L/C ...

- MOQ: Depending on which country you import to

Material: 100% polyester DTY yarn

Spec: 300D/96F

Intermingle: NIM / SIM / HIM

Lustre: SD/TBR/FD/CAT

- SD – SEMI DULL

- TBR – TRILOBAL BRIGHT

- FD – FULL DULL

- CAT – CATIONIC

Twist: 50-1200 TPM (TPM – TWIST PER METER)

Color: RW/DDB/ANY color

- RW – RAW WHITE

- DDB – DOPE DYED BLACK

Packing: Custom

Quality: High AA grade

Features:

- High Strength: The 300 denier (D) count means this yarn is relatively thick and strong, suitable for heavy-duty applications. It can withstand substantial wear and tear, making it highly durable.

- 96 Filaments: With 96 filaments, this yarn is composed of numerous fine fibers, which contribute to a smooth texture while retaining strength. This high filament count also provides a soft feel to the fabric.

- Elasticity: DTY yarn is designed with elasticity, making it stretchable and resilient. This property allows fabrics made from DTY yarn to retain their shape and recover easily after stretching.

- Wrinkle Resistance: Polyester DTY yarn is naturally resistant to wrinkles, helping maintain a smooth appearance in finished fabrics.

- Moisture Resistance: Polyester fibers have low moisture absorption, which makes the yarn quick-drying and ideal for use in various weather conditions.

- Colorfastness: It holds dyes well, resulting in vibrant colors resistant to fading, even with frequent washing and exposure to sunlight.

- Abrasion Resistance: The yarn's strong polyester fibers are resistant to friction and wear, increasing its lifespan in fabrics that undergo heavy use.

- Heat Setting: The yarn can be heat-set to achieve specific textures, such as crimp or bulk, enhancing the aesthetic and functional qualities of the fabric.

Application:

- Home Textiles: 300D/96F DTY yarn is commonly used in making curtains, upholstery, and heavy-duty fabrics for furniture coverings due to its strength, wrinkle resistance, and smooth finish.

- Outdoor Fabrics: The 300D/96F DTY yarn's durability and resistance to moisture make it suitable for outdoor products like tents, tarpaulins, and awnings.

- Automotive Textiles: 300D/96F DTY yarn is often used in seat covers, headliners, and other interior fabrics in vehicles due to its strength and wear resistance.

- Luggage and Bags: 300D/96F DTY yarn is ideal for the manufacture of backpacks, travel bags, and suitcases, as it can withstand rough handling while maintaining its integrity.

- Sportswear and Activewear: 300D/96F DTY yarn's elasticity and durability make it a great choice for sportswear, especially for items like tracksuits, leggings, and yoga wear, where flexibility and recovery are crucial.

- Industrial Fabrics: Due to 300D/96F DTY yarn's strength and resistance to environmental conditions, it is often used in industrial applications, such as conveyor belts, safety belts, and geotextiles.

- Heavy Garments: The yarn can be used to create durable outerwear, jackets, and work uniforms that require strength and resistance to abrasion.

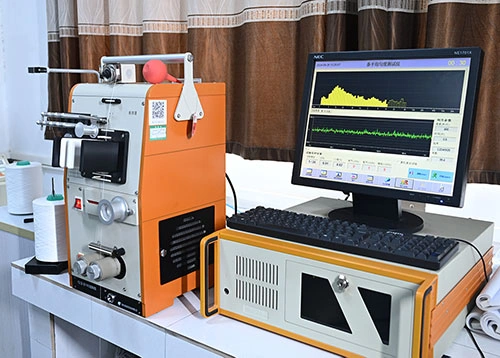

Yarn Testing Center

yarn twist

yarn twist yarn evenness tester

yarn evenness tester yarn defects tester

yarn defects tester yarn hairiness tester

yarn hairiness tester filament strength tester

filament strength tester yarn and thread testing center

yarn and thread testing centerOther Yarns

40s/2 Spun Polyester Yarnn

40s/2 Spun Polyester Yarnn 6s/1 Recycled Cotton Yarn

6s/1 Recycled Cotton Yarn 50s Cotton Yarn

50s Cotton Yarn Nylon Spandex Yarn

Nylon Spandex Yarn 70D/24F Nylon Drawn Textured Yarn

70D/24F Nylon Drawn Textured Yarn 70D/24F Nylon Textured Yarn

70D/24F Nylon Textured Yarn 300D Polypropylene Yarn

300D Polypropylene Yarn 6S/1 Recycled Cotton Yarn

6S/1 Recycled Cotton Yarn 900D/75F Polypropylene Yarn

900D/75F Polypropylene YarnMH Sewing Thread Factory

MH sewing thread factories are strategically situated in Ningbo and Hunan provinces, China, sprawling over an area of 130,000 square meters and employing over 1,000 skilled workers. Our production capacity consistently reaches approximately 3,000 tons of sewing thread monthly. MH is committed to ensuring a stable and timely supply of high-quality thread.

130,000m2

Plant Area

3,000 tons

Month production

1,000+

Workers

30,000m2

Warehouse

Shipping Methods

Lead Time: 25-35 days

Whatsapp:

Whatsapp: