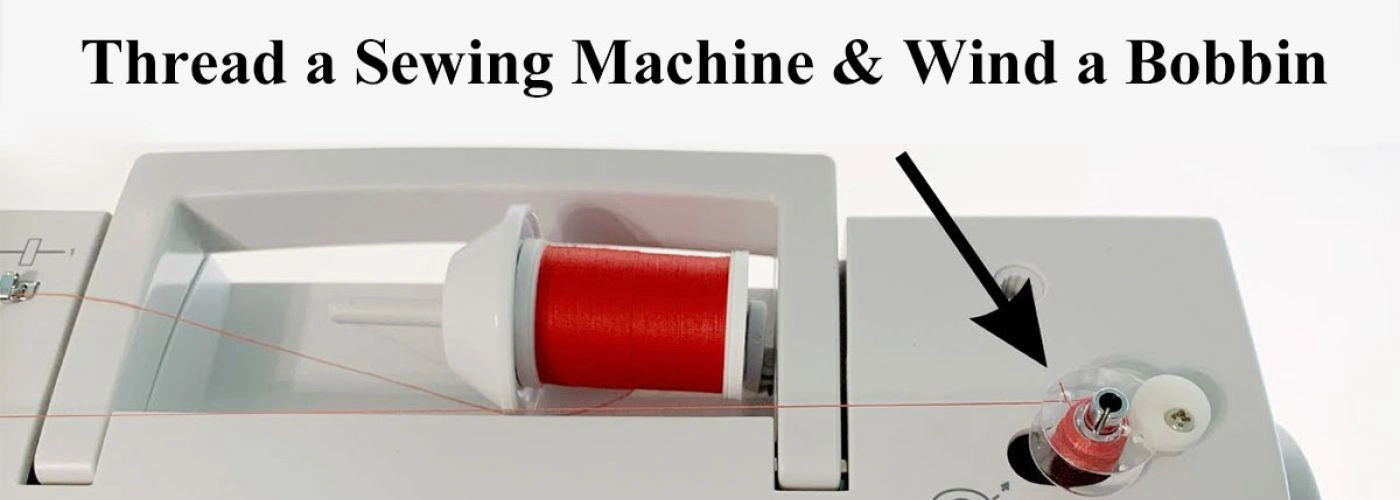

How to Spool Thread: A Guide to Threading a Sewing Machine & Winding a Bobbin

Threading a sewing machine and correctly winding a bobbin are essential skills for anyone embarking on sewing projects. Whether you’re a beginner or simply need a refresher, these two steps lay the foundation for seamless stitches and creative success. This guide will walk you through each process step-by-step, ensuring you’re ready to tackle your next project with confidence. Many newer machines feature lines and arrows to aid users in correctly threading the machine.

Preparing Your Sewing Machine

Locate the Spool Pin and Thread Spool

Before you start threading your sewing machine, it’s crucial to familiarize yourself with the spool pin and thread spool. The spool pin, typically found on the top of your machine, acts as the holder for your thread spool. The thread spool is the small cylindrical piece that holds your thread. Knowing the location and function of these parts will make the threading process much smoother. Take a moment to locate these components on your machine, ensuring you’re ready to proceed with confidence.

How to Thread a Sewing Machine

Threading a sewing machine might seem daunting at first, but with careful steps and a clear understanding of the parts, it becomes a smooth and straightforward process. Here’s how to do it:

Step 1: Place the Thread Spool

Begin by securing your thread spool on the spool pin. This pin is often located on the top or side of your sewing machine. If your machine includes a cap for the spool, affix it to hold the thread firmly in place. Using good quality thread is crucial as it prevents the spool from slipping or tangling during sewing.

Step 2: Guide the Thread Through the Threading Path

Every sewing machine features a threading diagram, often printed directly on the machine. Following this guide:

-

Pull the thread from the spool toward the thread guide. Ensure the thread fits securely into the slot.

-

Guide the thread down into the tension assembly, which often involves threading it through a tension disc or hook.

-

Keep the thread taut and pull it up into the take-up lever. The take-up lever usually has an opening or slit to hold the thread.

-

Finally, direct the thread downward toward the needle area.

Step 3: Thread the Needle

With the thread running smoothly, it’s time to thread the needle. Many machines offer a needle threader, but if done manually:

-

Cut the thread's end at an angle for a clean tip.

-

Push it through the eye of the needle, located just above the needle plate.

Once you’ve threaded the needle, pull about 5–6 inches of thread through to prepare for sewing.

How to Wind a Bobbin with a Sewing Machine

The bobbin may appear small, but it plays a vital role in creating evenly stitched fabrics. The process of bobbin winding supplies the lower thread that the machine uses to form stitches.

Step 1: Locate the Bobbin Winder

Identify the bobbin winder, usually found on the top or side of your sewing machine. Load an empty bobbin onto the winder spindle, ensuring it snaps securely into place.

Step 2: Prepare the Thread

Use the same thread spool that you’re threading your machine with, and follow the specific threading diagram for winding. Generally:

-

Lead the thread from the spool to the bobbin winder tension disc. This step creates the necessary tension to wind the bobbin evenly.

-

Pull the thread through one of the small holes on the bobbin’s side and hold it taut.

Step 3: Begin Bobbin Winding

Push the bobbin winder to the right (or into its winding position, depending on your machine model). Press the foot pedal or engage the start button to begin winding. Hold the thread tail securely for the first few spins, then release it.

Ensure the thread tail is not too long to prevent it from getting caught. Allow the thread to wind evenly across the bobbin. The machine will typically stop automatically when the bobbin is full.

Step 4: Cut and Load the Bobbin

Cut the thread connecting the bobbin to the spool. Position the bobbin correctly, often to the left, as specified in your machine’s manual. Remove the bobbin from the winder and trim any loose threads. Insert the bobbin into the bobbin case, ensuring it unwinds in the correct direction as specified in your machine’s manual.

Tips and Tricks

Choosing the Right Thread

Selecting the right thread for your sewing project is key to achieving even stitches and a polished finish. Here are a few tips to help you make the best choice:

-

Fabric Type: Match your thread to the fabric you’re using. Delicate fabrics like silk require a finer thread, while heavier fabrics like denim need a thicker thread.

-

Color Coordination: Choose a thread color that either matches or complements your fabric. This ensures your stitches blend seamlessly or add a desired contrast.

-

Stitch Type: Consider the type of stitch you’ll be using. Some threads are specifically designed for certain stitches, such as embroidery or quilting.

By following these tips, you can ensure your sewing project looks professional and holds up well over time.

Final Preparations Before You Begin Sewing

With both the top thread and bobbin thread in place, it’s time to bring the two together:

-

Hold the top thread with one hand while turning the handwheel with the other.

-

The needle will dip into the needle plate and pull up the bobbin thread.

-

Gently pull both threads to extend them by a few inches.

Your sewing machine is now ready to use! Ensure everything is set to work properly to avoid issues during sewing.

Final Check

Check the Thread Tension and You’re Ready to Sew!

Before you start sewing, it’s essential to check the thread tension. Proper tension ensures your stitches are even and your fabric lies flat. To check the tension, gently pull on the thread to see if it moves smoothly without being too tight or too loose. If adjustments are needed, use the tension dial on your machine to make the necessary changes.

Once your thread tension is set, you’re ready to sew! Insert the thread into the machine, and remember to leave a couple of inches of excess thread at the end of your seam. This ensures you have enough thread to complete your project without running out.

By following these steps and tips, you’ll be able to thread your sewing machine with ease and confidence. Happy sewing!

Why Correct Threading and Bobbin Winding are Critical to Ensure Proper Function

Threading a sewing machine properly and winding a bobbin evenly are essential for achieving professional-quality stitches. Improper threading or poorly wound bobbins can lead to skipped stitches, thread bunching, and even machine damage. Taking the time to master these steps ensures smoother sewing sessions and longer machine life.

Start Your Sewing Journey Today!

Threading your sewing machine and winding a bobbin may seem intimidating at first, but with practice, these processes become second nature. Getting these basics right means fewer interruptions and more time to focus on your creativity. Watching a video tutorial can enhance understanding and ease the learning process.

Looking for high-quality sewing supplies like sturdy thread spools or reliable bobbins? Check out our expertly-curated range of sewing essentials to elevate your experience. Your next project deserves perfection—get started today!

Whatsapp:

Whatsapp: