How do you fix a loose bobbin tension?

In embroidery, precision is everything. Every stitch counts and your bobbin thread tension can make or break your design. Whether you’re new to embroidery or a seasoned pro, understanding how to deal with bobbin tension issues is key. This will walk you through fixing loose bobbin tension and getting your stitches perfect every time.

What is Bobbin Tension and Why is it Important

Bobbin tension is the tightness or looseness of the thread coming from the bobbin. It’s a big deal in the quality of your stitches. If your bobbin tension is too loose, you’ll get uneven stitches and a messy underside. If it’s too tight, you’ll get puckering and thread breakage.

For embroidery lovers, getting the right bobbin tension means your projects look professional and perfect. When the bobbin thread is loose, it can ruin the design. So mastering how to adjust the bobbin tension is crucial for anyone who’s serious about embroidery.

Knowing how your embroidery machine works can help you solve tension issues. Understanding how the bobbin works with the top thread gives you insight into the problems. By learning these basics you’re better equipped to deal with bobbin problems.

Signs of Loose Bobbin Thread

Loose bobbin thread means uneven stitching with loops or loose stitches on the underside of your fabric. This happens when the bobbin tension is too loose and can’t hold the thread tight enough during stitching. Catching this early will save you time and rework. Getting the bobbin thread out of the bobbin case correctly is key to bobbin tension and good stitches.

When your design doesn’t sit flat or has loops, that’s a bobbin tension problem. It may also mean thread breakage or excessive thread usage. Take the time to check your work regularly to catch these issues before they get out of hand.

Pay attention to your embroidery machine and you’ll also notice bobbin tension issues. Listen for unusual sounds or irregular stitching and that’s a sign the bobbin tension needs to be adjusted.

Causes of Loose Bobbin Tension

Several things can cause bobbin tension issues. Incorrect threading, worn out bobbins or using the wrong bobbin can cause loose tension. Knowing the causes will help you deal with the problems better.

Improperly wound bobbins are a common culprit. If the bobbin thread is not wound evenly it can affect how the thread feeds through the machine. Make sure your bobbins are wound correctly and that will help with consistent tension. The bobbin race also plays a big role in bobbin tension, if the bobbin race is not adjusted correctly it can cause tension issues.

And using low quality thread can also affect bobbin tension. Thicker or inconsistent thread can cause tension issues. Using high quality, compatible thread makes a big difference.

Tools needed to fix sewing machine bobbin tension

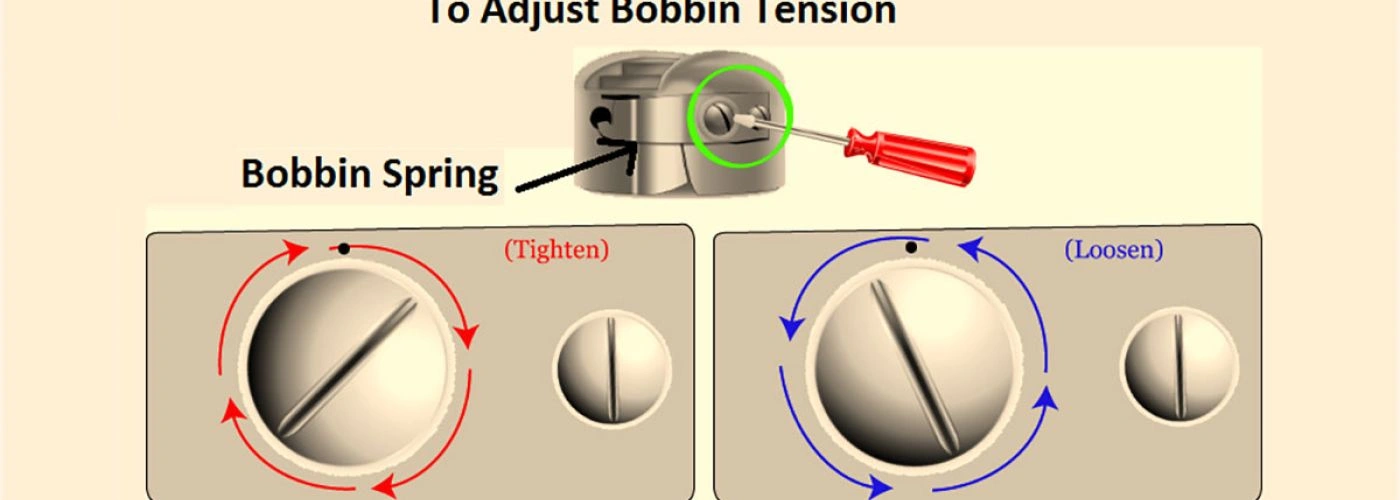

Having the right tools will make adjusting bobbin tension much easier. A small screwdriver is needed to fine tune the bobbin tension screw. You may also need a spool of thread, extra bobbins and your machine’s manual. Make sure to refer to your machine’s manual for instructions on how to load the bobbin, thread the machine and adjust the tension settings to get even stitches.

Buying a tension gauge is helpful if you adjust bobbin tension often. This tool will help you measure and set the tension. Not necessary for everyone but a good addition for serious embroidery lovers.

Organizing your workspace will also help with the tension adjustment. Having tools and supplies within reach will make the process smoother, less frustrating and more efficient.

Step by Step Guide to Adjusting Bobbin Tension

Adjusting bobbin tension involves several steps. First remove the bobbin case and check the tension screw. Using a small screwdriver turn the tension screw clockwise to tighten or counterclockwise to loosen the tension. Make small adjustments and test after each change. Remember to raise the presser foot while threading the machine, that will engage the tension discs and the thread tension.

After adjusting, put back the bobbin case and do a test stitch on a scrap fabric. That will let you see if the adjustment was successful. Continue to make small adjustments until the stitches are even and the fabric lies flat.

Make sure to note down the original tension setting before you make any changes. That way if the adjustments don’t give you the desired result you can go back to the original setting. Keeping a record will also help with future adjustments.

Test Your Adjustments

Once you’ve adjusted the bobbin tension, testing is key. Use the same fabric and thread you will be using for embroidery. That way the test will be relevant. Look closely at the stitches for any signs of loose or tight tension.

If the bobbin thread is too tight it will pucker or break the top thread. If the bobbin thread is too loose it will create loops on the underside. Adjust accordingly until you get balanced stitches. Balancing the top thread tension with the bobbin tension is key to avoid thread bunching or looping on the fabric.

Testing multiple times will give you a better feel of the tension adjustment. That will let you see how the machine will handle different stitching speeds and patterns and get consistent results on different projects.

Keeping Consistent Tension for Future Projects

Consistency is key in embroidery. Regular maintenance and checkups will help you keep your bobbin tension in top shape. Clean the bobbin area often to prevent dust buildup that can affect tension. Make sure the tension spring is clean and adjusted properly to prevent thread breaks and misstarts and to avoid damaging the bobbin case.

Using good quality materials also helps with consistency. Good threads and well wound bobbins will reduce the chance of tension issues. Investing in quality will pay off with less headaches and better embroidery results.

Regular checkups of your machine’s parts will prevent tension problems before they happen. Check the bobbin case and tension screws often and make sure everything is in good condition. Addressing wear and tear early will keep your machine in top shape.

Troubleshooting Ongoing Bobbin Case Tension Issues

If tension issues persist after adjustment, further troubleshooting may be needed. Understanding the different tensions of top thread and bobbin thread of your sewing machine is key. Check for mechanical issues like worn parts or misaligned components. Consult your machine’s manual or a professional technician for more information.

Sometimes tension issues are due to external factors like humidity or temperature changes. Monitoring your sewing environment and making adjustments will help minimize these effects.

Knowing your machine model will help you troubleshoot persistent issues. Online forums, tutorials and user groups will give you insights and solutions from other embroidery enthusiasts.

Fabrics and Threads

Different fabrics and threads will affect bobbin tension. Thicker fabrics or specialty threads will require different tension settings. Using thick thread will affect bobbin tension and may require adjustments as a bobbin filled with thick thread may not fit properly between the bobbin case and the tensioning plate and may cause stitching issues like puckering or breaking. Knowing these variables will help you adjust for each project.

Test your thread and fabric combination before you start a project and you’ll avoid tension surprises. You can make adjustments without compromising your final product.

Trying different threads and tensions will give you new effects and textures. Knowing how different materials interact will open up new possibilities.

Tips to Avoid Bobbin Tension Issues

Avoiding bobbin tension issues starts with maintenance and awareness. Clean your machine often and use good quality materials. Proper winding and storage of bobbins will also give you consistent performance. Make sure the machine is properly threaded to avoid tension issues while sewing.

Checking tension before each project will save you time and headaches. It will make sure you start each embroidery project on the right foot.

Learning about your machine’s specific requirements will prevent tension issues. Knowing your machine inside out will help you handle any problems that may arise.

When to Get Professional Help

Sometimes despite your best efforts tension issues will persist. In that case getting professional help is smart. Knowing sewing machines and their maintenance is key as technicians can diagnose underlying problems and offer solutions that may not be obvious.

Professional servicing is especially helpful if your machine frequently has tension issues. Regular maintenance will extend the life of your machine and improve its overall performance.

Knowing when a problem is beyond your expertise is an important step. It will save you time, prevent damage and ensure your machine will continue to run smoothly.

Conclusion Your Road to Perfect Stitches

Learning bobbin tension adjustments will improve your embroidery skills and results. By understanding the mechanics, identifying the issues and making thoughtful adjustments you’ll get consistent stitches. With practice, patience and the right tools you’ll become proficient in managing your embroidery machine’s tension. For more information join embroidery communities or seek expert advice to learn more. With persistence your embroidery projects will show your skill and creativity.

Whatsapp:

Whatsapp: